Intensity Splitters, Plate/Cube Splitters / Polarizers

Intensity Splitters, Plate/Cube Splitters / Polarizers

Intensity Beam Splitters

Beamsplitters are made either in Plate or Cube form. It is important to note that semantics have categorized Beamsplitters as either splitting the beam intensity over wavelength or splitting the spectrum. In this section, we will treat Beamsplitters as optics that split intensity. We will reserve splitting spectrum in another section which utilizes such acronyms as, Edge Filters, Longwave, Shortwave Pass, Hot, and Cold Mirrors. Plate Beamsplitters are a simple coated plano optic. On the other hand, Cube Beamsplitter are usually made of two right angle prisms, where the hypotenuse of one prism is coated. Beam Splitting can be desired for something as simple as reducing intensity to creating a complex device, such as, optical alignment or interferometry. Cube Beamsplitters can be an excellent alternative from Plate Beamsplitters when beam displacement is an issue. However, the transparency range of optical cements used to assemble Cube Beamsplitters limits their spectral application to, roughly, 0.200 to 2.5µ. Plate Beamsplitters do not require assembly and their applications are only limited by the transparency range of the selected coating and substrate materials used. These Intensity Beamsplitters can be designed to split the Average Polarization sate or Polarized to split S and P states at desired values of intensity.

All Cascade Optical Corporation's Dielectric coatings pass MIL-C-48497 and can be made to pass even the severe abrasion requirements of MIL-C-675. We have a Environmental test Lab department to qualify each and every coating run.

Beam Splitters For Intensity, Alignment, And Interferometry

Below are some featured Coatings where customers wanted to split the beam intensity for various applications

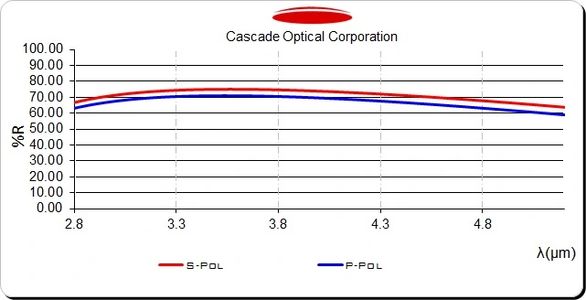

Plate - ESO/ Cascade BS T/R=30/70% 2.8-5µ (L&M Band) @ 20º

In this particular case the Astronomer wanted to split up the intensity for two reasons: The customer wanted to utilize a filter to create neutral density across both the L and M band and to utilize 30% of the light to align the device. It was also important to them to minimize polarization effects. This IR coating was coated on ZnSe. Due to the high index of ZnSe there was also an AR on the back side

Cube - Rs/Ts=50/50%±1% 680-780nm Cube BS

This customer wanted a very flat BS from 670-800nm for an Interferometer. Due to the internal angle of incidence, the cemented gap and index difference between, the coating materials and Bk7 cube there are heavy polarization effects. Accordingly, we recommended an S-Polarization preference. With this preference we were able to maintain their tight 1% tolerance. In this particular example the customer was not interested in Tp

Plate - R >99% @ 1310, Rav < 3% @450-650, & R = T = 50% ±3% @ 1064 nm @ 45º

The US Navy wanted quite a challenging and multi-faceted BS design for MW range 1064nm Laser Power. Although the exact purpose of this optical element is not publicly know, it is clear this optic is unique and highly classified

Plate And Cube Polarizer

It may be necessary to polarize light in order to "clean up" a signal and obtain a better Signal To Noise ratio(S/N). This can be especially important in fiber optics or optics where the signal is carried over large distances. We are able to achieve Tp/Ts>1000 over a very broad range

Plate - POL For Telecom 1550nm C Band at Brewster's Angle

This Telecommunications company sought out our services to Polarize light that would be coupled into PM or Polarization Maintaining Fiber. In this case, the customer did not really have a specific angle of incidence in mind. So, Cascade suggested we utilize the Brewster's angle to facilitate the best possible Tp Transmission while the coating design's interference layers went to work on reflecting the remaining Ts. This angle is 56.13º for air to FS. Here we see Tp is maximized and Ts is -37db or 0.02% reflectivity or Efficiency of Tp/Ts>5000 which is excellent for a Plate BS

Plate - POL for VIS and NIR

This customer works in the Biosciences and has a product that replaces human eye lenses after cataract eye surgery. For their particular application they requested a VIS Pass and then a secondary POL at 850nm

Cube - BS Ts/Tp>60db Telecom S, C,& L Band

With a high internal angle of incidence and a large Cube and coating material index offset very large polarization effects are induced. So, It takes fewer layers than a Plate to Reflect Ts. For the same reason, the wave band is typically much broader than a Plate. The other benefit is there is no beam displacement. But, again, transparency is limited by optical cements. For some IR applications, it may be necessary to create >lambda/20 flat Hypotenuses and contact them under vacuum

In some ultra, extreme applications the Extinction coefficient, defined as the ratio between Tp and Ts has to be as high as 100,000. The plot to the right shows performance of the Cube BS designed for S, C and L Telecom bands having a Ts to Tp, staggering, ratio of more than 60db

Submit Specifications below:

Cascade Optical Corporation | 1225 E hunter Santa Ana Ca 92705 | sales@c-optical.com | (714) 543-9777

Copyright © 2023 Cascade Optical Corporation - All