Durable "Cold Coatings" Lower Than 66ºC

COLD COATING ANTI REFLECTION

Cold Coating Anti Reflection

Our flexible range of thin film deposition services include a low temperature processing we refer to as IOPLAS-II. It is a specialized form of Ion Assisted Physical Vapor Deposition. This innovative technology is applied to generate high packing densities with, low stress, low scatter, and high laser damage resistance. Although quite a few companies now have incorporated this technology in their systems, they may or may not, know how to use it. Through years of experience, we have fine tuned just the right amount of energy density for almost every coating and substrate type. Cascade has been a pioneer, in that we have incorporated this technology back in the early 80s. We can coat more than 30 Layers or greater than 5µ thick coatings on PC, Doublets, and other delicate Crystals. What is most exciting about our IOPLAS-II coatings is that we have developed them to pass all the Environmental testing per MIL-C-48497 and LIDT >10GW/cm2

All Cascade Optical Corporation's Dielectric coatings pass MIL-C-48497 and can be made to pass even the severe abrasion requirements of MIL-C-675. We have a Environmental test Lab department to qualify each and every coating run.

IOPLAS-II Fibers And Other Temperature Sensitive Materials

Below are some featured Coatings where customers wanted coatings on the ends of fibers with high LIDT, Cemented Lenses, and Plastic Optics

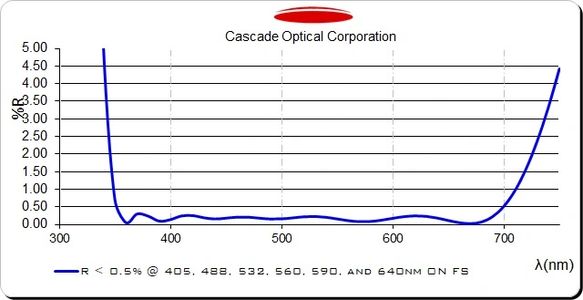

High LIDT BBAR On The Fiber Tips

This customer wanted us to cover several laser lines of interest, simultaneously, on fiber ends at 405, 488, 532, 560, 590, 640nm. The other hurdle was that they required 5.1MW/cm2 laser power at 405nm. Rather than creating 7 V-Coats it is actually easier to create a BBAR that covers all of these laser lines. This also reduces the number of coating layers and makes the overall coating more resistant. Given UV friendly material types and the correct processing parameters we met this challenge head on and have been in production for years

Coating Cemented Lenses, Doublets, Or Prisms

This is an example of an extended BBAR we did for a very well known telescopic lens manufacturer on CaF2 Doublets. Note how this coating is in the NIR and since interference layers need to be proportionately equal to the thickness of the wavelength, the overall coating thickness is much greater than a VIS BBAR. This particular coating was done on temperature sensitive CaF2 Doublets and passed both adhesion and severe abrasion MIL-C-48497

Cold Coating Aviation Flight Goggles

This customer was not only looking for a Visible Broad Band Anti Reflective Coating, But, they also wanted a Multi-Layered Notch centered to block out a specific laser line in the visible(Blinding Protection)

Submit Specifications below:

Cascade Optical Corporation | 1225 E hunter Santa Ana Ca 92705 | sales@c-optical.com | (714) 543-9777

Copyright © 2023 Cascade Optical Corporation - All